EASYboss®

Podrobnosti k výrobku

-

Overview

- Side snap-fit assembly

- High axial load-carrying capacity due to large bearing surface

- Reduced component weight

- No corrosion

- Consistent tightening torques

- No catching of the parts

- Easy, no-damage disassembly

- Recyclable

Branislav Gunda

The most suitable clip

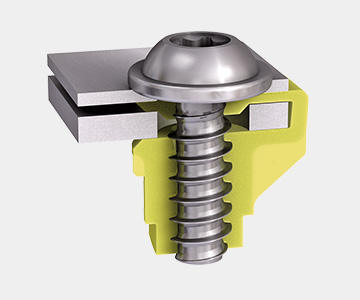

Development focus of the EJOT EASYboss® was the design of an all-around improved alternative to the still commonly used sheet metal clips. Main fields of application for the EASYboss® are designs where direct assembly is not possible. Reasons for this are insufficient installation depths in the component or other tool related conditions. Further possible uses are in thin-walled components made of different materials, for example thin sheets. The EASYboss® is assembled through snap fitting sideways to the fastening direction from the edge of the part or through an access hole in a flat component. Tolerances of the hole pattern can be reliably compensated by the fastening element. For varying material and hole wall thicknesses a range of different sizes are available. In particular the combination of EJOT EVO PT® screw and EASYboss® offers ideal prerequisites for the direct assembly into plastic.

![[VBT_EVO_PT].png](/medias/sys_master/products/products/h0d/h92/9356537593886/135Wx135H-.png)